The Fuji Oil Group's Path to Developing the Potential of Food Ingredients

Since our founding in 1950, the Fuji Oil Group has sought the happiness and wellbeing of people and the Earth through food. In so doing, we have followed the path of innovation and challenges.

This corner, divided into three chronological sections covering the past to the present, revisits the path we have traversed as we seek to develop the potential of food ingredients in accordance with the Fuji Oil Group Management Philosophy.

1950s-1960s

"Imitation is Not the Way" – Establishing Original Technology

-

1950

Fuji Oil established

The history of Fuji Oil began in the oil product plant of its predecessor, Fuji Sanshi.

Read More

During the period of rationing after WWII, the company found it difficult to procure rations of raw materials for oil and fat. As a result, the company decided to develop products that distinguished itself from other companies and that used different raw materials. Our predecessors embraced the idea that there was no reward in copying others and the importance of fostering uniqueness, no matter how minor. Our journey towards innovation and challenge begins.

-

1951

World’s first oil from pressurized extraction of copra

Japan at the time had not yet commercialized palm oil for use as a food ingredient.

Read More

However, Fuji Oil focused on palm oil as a raw material due to great expectations for expanded use in food-based applications that could be achieved by taking advantage of the characteristic of palm oil as a tropical oil that hardened at room temperature.

We were able to achieve uniqueness in our raw materials and technology by becoming the first in the world to successfully establish pressure extraction technology, which involves an initial pressing of copra (dried coconut meat) followed by a secondary processing to extra more oil.

-

1954

Japan’s first palm kernel oil extraction

Amid our pursuit of uniqueness under the spirit of "there is no reward in copying others", we focused on palm kernels (the seed at the center of the coconut palm) as a raw material, something that had never been done before, to establish the first palm kernel oil extraction technology in Japan.

Read More

Began development of hard butter, a substitute oil for cocoa butter, the raw material used to make chocolate.

-

1955

Manufactured Japan’s first hard butter

Launched sales of the hard butter "Melano Butter" in 1955.

Read More

At the time, it was strongly believed that no hard butter for chocolate could replace cocoa butter, so there was a strong negative reaction to hard butter.

However, we conducted a sales promotion involving manufacturing our own chocolate to prove the high quality of Melano Butter. This lead to gradual brand recognition. In 1959, "Melano Butter SS", a new, high quality hard butter, was born. Resolve the issue of fat blooming (chocolate turns white in color), one of the weaknesses of cocoa butter. Hard butters continued to gain acceptance as a raw material for chocolate thanks to a high melting point that was optimal for seasonal temperatures.

-

1960

Published Basic Management Principles

To mark our 10th anniversary, then senior executive manager Masataro Nishimura (who would go on to become the 2nd president of Fuji Oil), created the Fuji Oil Basic Management Principles as a charter for management.

Read More

In 1981, this was revised to further clarify purpose and simplify language. Asserted the fundamental philosophy of "achieving ceaseless growth by accomplishing customer satisfaction", "challenging innovation continuously with a spirit of creativity", and "enriching individual character through vigorous self-enlightenment."

-

1961

Started using defatted soybean protein

With the deregulation of soybean imports in 1961, oil companies began releasing products, including breads, biscuits, and noodles, using defatted soybeans.

Read More

However, Fuji Oil's vision was to focus on developing high-protein soybean meal, so we remained dedicated to our policy of improving quality by using soybean replacements or using soybeans as a raw material, and stayed committed to our R&D efforts.

The result was the development of "Fuji Takaramame" in 1961. This was a defatted soy protein product that served as a raw material for miso fermentation, tofu, fried tofu, and more. Not only did this product improve work efficiency at tofu shops, it also contributed to improving the functionality and quality of tofu and fried tofu as final products.

-

1963

Developed Japan’s first ganache

At the time, Fuji Oil was challenging itself to extract cocoa butter from the cacao powder using to make cocoa drinks.

Read More

It was during this process that we discovered the key to developing chocolate for coating. In 1963, we released Choco Fancy, a coating chocolate that was made by combining with hard butter. We also launched sales of Choco Fancy for confectioneries and ice cream.

At the time, milk chocolate was the main type of chocolate sold but Choco Fancy was unique for its black color and shiny gloss. At first, consumers were wary of the black color but they did find the gloss appealing. It was after this that black-colored ganache became common. Later, our chocolate coating would be used in the manufacturing of a wide variety of products, including biscuits, confectioneries, and breads.

-

1966

Established gel forming soy protein manufacturing method, acquired patents in 10 countries

As the use of defatted soybeans advanced, we established a gel molding method for soy protein isolate, which has a high protein content.Secured patents in in ten countries.

Read More

In 1966, we launched sales of Fujipro, a product with superior viscoelasticity and emulsifiability. Helped develop a new market for soy protein isolate as an ingredient for improving the function and quality of sausage and other processed foods.

-

1968

World’s first sterile filling production for high-fat cream

As Japanese continued to adopt more western diets, preferences began to shift from traditional snacks and Japanese confections to cakes.

Read More

However, due to fresh cream quality being unstable due to the nature of milk fat, there was the problem of these products having a short shelf life. We focused on this issue and aimed to create a whipped cream that was both delicious and long-lasting. We succeeded in developing a cream made from a plant-based oil. As a result, we launched sales of the whipped cream Topping in 1968. Previously, cream products were only available from stores within same-day delivery distance of the production factor. However, this product made whipped cream available to stores around Japan. Butter cream had been the main method of decorating western confections but this development created the significant opportunity for consumers to switch to a whipped-cream by topping.

-

1969

Engaged in margarine business

1970s-1990s

Contributions to Diversified Japanese Food and Global Expansion

-

1971

Started operations at Hannan Plant

Constructed the Hannan Plant (Izumisano, Osaka) as a large-scale shorefront plant with the goal of establishing an international food company through scope expansion and optimization.

Read More

A major issue was pollution prevention measures. We implemented thorough pollution prevention measures, including installing an internal power generator, ensuring wastewater treatment, installing a powered dust collector to prevent air pollution, and installing activated sludge treatment facilities.

-

1977

Opened Fuji Sunny Plaza Tokyo

The 1970s marked Japan's emergence as a mature society and advanced growth. With a focus on discovering changes in people's needs and preferences, and increasing communication with our customers, we decided to establish a confectionery production center that promoted co-collaboration with customers on product development.

Read More

Based on the basic concept of being a place for identifying client needs and providing technical services, in 1977 we established Fuji Sunny Plaza Tokyo, the first Fuji Sunny Plaza facility.

-

1978

Listed to TSE First Section

-

1980

Started Japan’s first sales of plant-based cheese materials

Cheese cake from France was introduced to the Japanese western confectionery industry but confectionery shops faced the problem of not being able to obtain the all-important cheese for cake baking due to issues related to production capacity and transport.

Read More

Our company had previously been working on research to develop a cheese-flavored ingredient. We accelerated this research and added other technologies such as emulsified fermentation to successfully develop Japan's first plant-based cheese-flavored ingredient (a filled cheese made by using fat-free milk solids, replacing milk fat with plant fat, and fermentation). In 1980, we launched sales under the product name Quvearl and later enhanced the product lineup. In addition to confections and breads, the product gained popularity as a new ingredient for use in desserts and frozen confectionery.

Established enzymatic interesteri cation technology

With full-scale bio research underway, we began research into fermentation technology and enzyme utilization technology.

Read More

In 1980, we established enzymatic interesteri cation technology. This technology enabled the world's first production of hard butters for chocolate using sunflower oil.

-

1981

Established FUJI OIL(SINGAPORE)

We first engaged in overseas markets by establishing extraction plants in Malaysia in 1973 and the Philippines in 1974. However, we faced the realities of overseas expansion when trying to deal with local investments and national policy, and were forced to withdraw from those businesses.

Read More

In 1981, we established FUJI OIL (SINGAPORE) as a core plant for conducting product exports out of a central Asian market to markets around the globe.

After expanding into Malaysia in 1986, the United States in 1987 and Belgium in 1992, Fuji Oil embarked upon a path on the world stage, seeking to develop the potential of food ingredients.

-

1988

Tiramisu boom driven by cheese-flavored ingredient Mascapone

Fuji Oil employees who learned about Italy's tiramisu during a research trip to Europe saw the possibility of expanding tiramisu to Japan, where it was virtually unknown.

Read More

Fuji Oil started development of a plant-based fermented lactic acid ingredient to serve as a substitute for mascarpone, the main ingredient in tiramisu. We succeeded in creating "Mascapone" comparable to conventional mascarpone in terms of shelf life, workability, quality stability, and price, and launched sales in 1988. With growing popularity among young women, a feature published in a trend magazine at the forefront of pop culture resulted in an almost overnight boom in popularity. Tiramisu grew to become a revolutionary product that changed the landscape of the dessert scene and also caused a dramatic rise in orders for our Mascapone.

Fuji Oil's role in developing a hit product so popular that the phrase "tiramisu effect" was coined helped garner attention within the confectionery industry for our concept proposal capabilities. This also made us aware of the importance of product proposals and sales.

-

1989

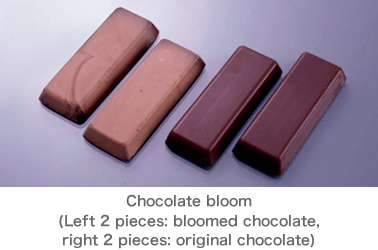

Established revolutionary product to prevent chocolate blooming

Chocolate made from cocoa butter requires a tempering (heat adjustment) process to prevent fat blooming.

Read More

In 1989, we used our cumulative knowhow from fundamental research in fats and oils to transesterification technology to develop Chocoseed. Adding this seed agent to chocolate raw materials makes it possible to omit the tempering process and reduce chocolate manufacturing times. In addition to the benefit of not experiencing fat blooming after melting and rehardening, the workability of the chocolate is also improved. This expanded application to include chocolate that is frozen and eaten, and chocolate that combines baked confections with bread.

-

1993

Completed water soluble soybean polysaccharide production technology

Water soluble soybean polysaccharides are a unique ingredient that enables the advanced use of okara (soybean meal).

Read More

Water soluble soybean polysaccharide can be used as a stabilizer that prevents sedimentation in lactic acid beverages, and are widely used by the beverage industry. Water soluble soybean polysaccharide also is used as a noodle loosening agent and for improving the workability of rice, resulting in broadbased use in the lunch boxes and other food sold in convenience stores. Today, water soluble soybean polysaccharide has grown to become a mainstay business that represents an income pillar in our soybean segment.

2000s-

Aspirations to Be a Global Company Contributing to the Happiness and Wellbeing of People and the Earth

-

2007

Established technology that uses transesterification to create low trans fat oils

Recent research has shown that excessive consumption of trans fatty acids contained in products such as margarine leads to increased levels of bad cholesterol and increase the risk of heart disease.

Read More

Fuji Oil established low trans fatty acid technology in 2007, putting us in the position to rapidly respond to the growing need for low trans fatty acid in America and other markets around the world. This technology enables the production of foods that are not only delicious, but also that greatly reduce trans fatty acid levels, helping us deliver safe, healthy foods to consumers.

-

2010

Developed production technology with flavor enhancement functions

In 2010, we developed the DTR manufacturing method for creating oils and fats with enhanced flavor that highlight saltiness, spiciness, and acidity despite using lower amounts of salt and seasonings.

Read More

In 2011, we launched sales the A functional oils with "DTR technology".

-

2012

Developed world’s first USS manufacturing method

In light of future environmental and resource issues, and to fulfill our commitment to using the power of the soybean to make major contributions to the health of people and communities, Fuji Oil has been proactively involved in technology development related to all facets of the soybean.

Read More

In 2012, we succeeded in using our USS (Ultra Soy Separation) manufacturing method, the world's first patent manufacturing method for this technology, to develop soy cream and low-fat soy milk as new soybean ingredients. Soy cream and low-fat soy milk use a process similar to milk isolation to separate soybeans and provide delicious taste and function that were not available with conventional soybeans.

Products using soy cream and low-fat soy milk include cheese and mayonnaise products, pioneering a new age for delicious and healthy lifestyles.

-

2015

Opening of first offshore research & development center

Fuji Oil opened the Asia R&D Center, the company's first offshore research & development facility, in Singapore to equip ourselves with a more locally connected organization and explore solutions in closer collaboration with consumers.

Purchased Harald, a major Brazilian industrial-use chocolate manufacturer

In 2015, Fuji Oil purchased shares in Harald, one of Brazil's largest industrial-use chocolate companies.

Read More

This move marked a major step into global expansion for our chocolate business. By rolling out products with our oils and fats technology complemented by Harald's brand and sales channels, we will put out high-quality, high-performance chocolate products that support the spread of a new culture of chocolates in South America.

Switched to group company structure

In October 2015, Fuji Oil transitioned to a group headquarters system out of a strong sense of crisis that if we innovate slower than the pace of change happening in the world, then we cannot survive in a global market.

Read More

The objectives of the Group company are to enhance the Group’s strategic functionality, strengthen governance, Hitozukuri (fostering people), and create new businesses. We started building a management platform that will support continuous growth and enable us to contribute to society.

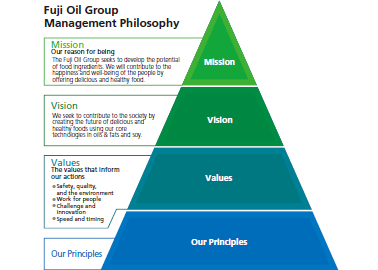

Established the Fuji Oil Group Management Philosophy

Created the same year when we transitioned to a Group company structure, the Fuji Oil Group Management Philosophy promotes common values between all Group employees and serves as the foundation for Group governance to set standards for decision-making and employee conduct.

Read More

In addition to carrying on our founding spirit, the Fuji Oil Group Management Philosophy outlines our Group mission, our ideal structure, and the values and ethics we must adhere to in our business activities.

The mission outlined in the Fuji Oil Group Management Philosophy (Our Mission) is to pursue the possibilities of food ingredients and contribute to food happiness and health.

All our Group employees are united in our commitment to happiness for people and communities as we work to resolve social issues.

-

2016

Development DHA/EPA stabilization technology

DHA and EPA are mainly found in fish oils, and consumption are believed to help prevent lifestyle diseases, heart disease, dementia, and other illnesses.

Read More

On the other hand, DHA and EPA oxidize quickly compared to other oils, and with deterioration due to oxidation, DHA and EPA the release a distinctive "fish smell".

Consuming DHA and EPA usually entails eating fish or taking a capsule-shaped supplement, and their use in general foods is considered difficult.

For several decades, we have continued R&D based on the theme of health fats and oils, and in 2016, we successfully developed the world's first "stable DHA and EPA", which dramatically reduces deterioration due to oxidation. The dissemination of foods containing stabilized DHA and EPA will enable the delicious and easy consumption DHA and EPA, levels of which are typically insufficient in the diets of most people.

Created Responsible Palm Oil Procurement Policy

We drafted and announced the Responsible Palm Oil Procurement Policy in 2016 as an approach to be adopted by the entire Fuji Oil Group.

Read More

his policy promises the procurement of palm oil produced using responsible methods from suppliers who respect human rights and the environment. We work with stakeholders to ensure procurement in line with this policy. We will continue working to develop the potential of food ingredients and to contribute to the happiness and well-being of the people by offering delicious and healthy food.

Opening of the Fuji Science and Innovation Center

With the transition to a group headquarters system in 2015, the center of our leap to a new stage was the establishment of this facility as a place for spurring innovation through the combination of knowledge and technology originating from both Fuji Oil and elsewhere.

Read More

By serving as the headquarters of the group's global network for research and technological development to identify the needs of the world's markets and contributing to society with delicious and healthy food, we seek to fulfill our vision by creating the future of delicious and healthy foods.

-

2017

Formulation of the Fuji Oil Group Human Rights Policy

While maintaining interactive communication with stakeholders, The Fuji Oil Group seeks sustainable development in harmony with society by contributing to society through our business.

Read More

On April 1, 2017, we formulated the Fuji Oil Group Human Rights Policy in accordance with "work for people," the value declared in the Fuji Oil Group Management Philosophy.

Establishment of UNIFUJI

Fuji Oil established a joint venture in Malaysia for the production and sale of palm oil products with high added value and made from sustainable palm oil. This way, we can procure palm oil produced in a responsible manner from suppliers who respect people and the global environment, in accordance with our Responsible Palm Oil Procurement Policy.

-

2018

Formulation of the Responsible Cacao Sourcing Policy

Cacao is an important raw ingredient for the Fuji Oil Group.

Read More

So that we can continue delivering happiness through foods on into the future through products made with sustainable cacao, and to make a contribution to the United Nations' Sustainable Development Goals, we have formulated the Fuji Oil Group Responsible Cacao Sourcing Policy.

In accordance with this policy, we are committed to working with a wide range of stakeholders in the cacao supply chain as we source sustainably grown cacao throughout our business.

Entry into the Dutch Food Valley

Through Fuji Europe Africa B.V., established in October 2018, the Fuji Oil Group became a member of the Dutch Food Valley community located in Wageningen, the Netherlands.

Read More

The Dutch Food Valley holds a concentrated store of knowledge on agriculture and foods. As a member of the Food Valley, Fuji Oil will expand our global R&D network and drive open innovation. We will thus provide Plant-Based Food Solutions that address the diversifying needs of consumers as we seek to contribute to customers and society with delicious and healthy food.

-

2019

Acquisition of Blommer Chocolate Company

In 2019, Fuji Oil acquired Blommer Chocolate Company, One of the largest industrial chocolate company in America.

Read More

Blommer was established in Chicago in 1939. Blommer is the largest cacao processor and ingredient chocolate supplier and second-largest industrial chocolate company in North America. Blommer has an intimate relationship customer, a consistent R&D capability from beans to final product, and strong in initiatives for sustainability.

With the addition of Blommer, Fuji Oil Group is increased presence in Pacific Rim market and the U.S. market. This is a union in which the two companies’ strengths and knowledge complement each other perfectly, including business areas, business regions, customer networks and sustainability of main raw materials. Our mutually complementary strengths will drive business across the Group.