Ensuring Product Safety and Quality

Material Issue

Product Safety and Quality

Management information

Relevance to our business

As a food ingredient manufacturer and participant in food supply chains, we recognize our potential impact on food safety. We believe that it is important for us to ensure food safety and quality in full consideration of all processes, from product design, through raw material procurement, manufacturing, and shipping, to consumers’ consumption of our products.

Basic approach

Providing safe, quality products is a prerequisite for a food manufacturer. The Fuji Oil Group has established a Basic Policy of Quality* and a quality assurance system that we continually work to improve. This system covers from product design to delivery to the customer (both B-to-B customers and end consumers), with the highest priority placed on product safety and quality consistency. We believe that we can contribute to comprehensive food safety and quality by enhancing our quality and food safety management. We do this based on our Quality Assurance Regulations and by continuing to promote activities to raise employees’ quality awareness.

Management system

The ESG Division Officer oversees initiatives in this area. The Sustainability Committee,*1 an advisory body to the Board of Directors, monitors the progress and results of initiatives as a material ESG issue.*2

Goals / Results

At least 90% complete At least 60% complete Less than 60% complete

| FY2022 Goals | FY2022 Results | Self-assessment |

|---|---|---|

| Raise quality awareness of employees in order to achieve zero serious quality-related complaints* |

|

|

| Strengthen communication with quality managers at Group companies and promote a food safety culture and the sharing of quality-related information |

|

-

* Incidents concerning food products that are harmful to health or violate the law, and require a recall.

Analysis

The COVID-19 pandemic has increased the workload of managers in various ways, including the need to prevent and control infections within their teams. However, thanks to efforts to maintain hygiene at production sites through continuous corrective actions and preventive measures, there were no serious quality-related complaints (recalls) in FY2022. Moreover, the quality-related information sharing platform we developed to improve quality assurance levels and share quality information across the Group has now made it possible to regularly send and share quality information across companies and national borders. We also strove to raise quality assurance levels by creating opportunities for quality managers to learn from other companies by sharing examples from their own company on specific topics.

Next step

It is essential to reduce quality-related complaints and improve the level of quality assurance in Group companies. To address these issues, we set the following goals for FY2023.

- Raise quality awareness of employees in order to achieve zero serious quality-related complaints

- Strengthen communication with quality managers at Group companies and promote a food safety culture and the sharing of quality-related information

Specific initiatives

Risk management and countermeasures

Enhanced quality management system

Since early 1990s, some Fuji Oil Group companies started a quality management system to ensure that the Fuji Oil Group Basic Policy of Safety, Quality and Environment is applied to their business activities. In addition, the Group established the Quality Assurance Regulations in order to monitor the management status of each Group company based on these regulations through safety, quality and environmental audits.

Customer complaints and quality related inquiries are received by the Fuji Oil Group’s sales division and customer service desks. This information is examined by the Quality Assurance Department or other teams responsible for quality assurance at each Group company and then further investigated by the relevant departments. From there, the department responsible for the quality-related issues carries out checks, and the sales division provides a response to the customer.

Each Group company also collects and analyzes data on the customer complaints they receive. Fuji Oil Holdings Inc. aggregates and analyzes this data and reports it to the Management Committee Meeting for sharing across the entire Group.

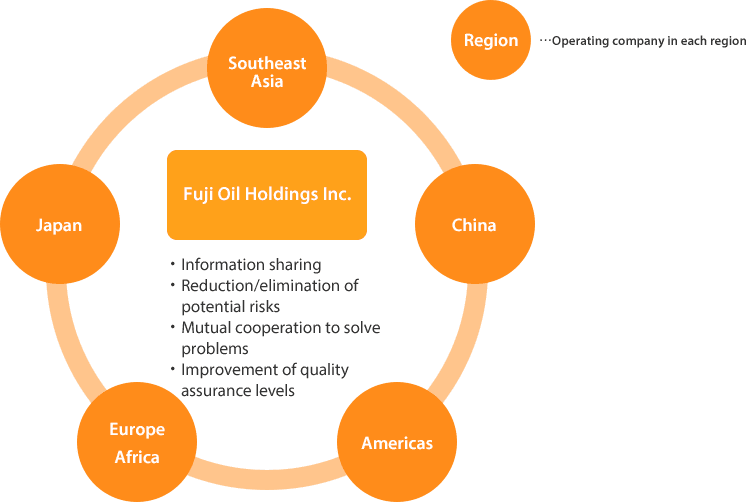

Fuji Oil Holdings Inc. also works to build the Group’s network of quality managers and share initiatives, best practices, and management know-how across organizational boundaries within the Group, with the aim of promoting holistic information sharing among quality managers and improving the quality assurance system. We are leveraging this network to share experiential insights across Group companies and update each Group company on the latest food regulations and international trends in food. This enables us to reduce and eliminate new issues and potential risks related to product safety and quality and make continuous improvements toward higher standards of safety and customer trust. Furthermore, this allows to resolve problems that do arise more quickly and collaboratively, avoiding any inconvenience to our customers.

Acquisition of Management Certifications

Group companies’ management certification status

Risk management methods for food safety

Fuji Oil Group companies and their relevant organizational units manage and respond to food safety risks as part of the Group’s overall risk management system.*

Food safety-related risks and countermeasures

In FY2022, the risk assessment once again identified food safety-related risks, including contamination with foreign matter, allergens and inappropriate raw materials. We have been working to reduce these risks by acquiring certifications on food safety and quality management, conducting focused evaluations, providing guidance and implementing improvements on these risks through internal audits, and intensifying the implementation of 3S and 5S methodologies.

Education

The Quality Assurance Department or the department in charge of quality assurance at each Group company plans and provides appropriate training to employees to raise quality awareness in accordance with local conditions. For example, Fuji Oil Co., Ltd. supports activities at each plant conducted in accordance with the action guidelines and holds lectures on hygiene and other matters. In FY2022, the annual hygiene lecture was canceled again due to COVID-19. Instead, we carried out educational and awareness programs in each workplace by creating and distributing quality-related educational materials along with a quiz for assessing employee understanding of the topics covered.

In addition, every November we participate in Quality Month, which is organized by the Quality Month Committee, a Japanese industry organization. During Quality Month, we conduct various activities focusing on predefined themes to raise awareness on quality among our employees.

We have also continued providing Group companies outside Japan with technical guidance on newly introduced analytical equipment to improve the overall quality management level of our Group. We will continue promoting technological exchange among Group companies to enable wider use of the Group’s advanced analytical techniques, and to provide safer and more reliable products to our customers worldwide.

Product labeling

Information indicated on labels of products varies considerably depending on the country where the product is sold. The Quality Assurance Department or the department in charge of quality assurance at each Group company collects information to ensure that product labels comply with the laws and regulations of each country and region.

At Fuji Oil Co., Ltd., the Quality Assurance Department collects information daily on relevant laws and regulations, and issues updates on any revisions to the relevant departments via the regularly distributed “Food Safety Information,” in order to ensure that these revisions are promptly and accurately reflected in product labels. We also have a system in place to ensure that the staff in the development, production and quality assurance departments check the content of product labels before printing to avoid any errors that would violate laws or regulations. We strive to enhance transparency by disclosing information to our customers in a timely fashion through product specifications and the Fuji Oil Co., Ltd. website.

In FY2022, no serious labeling violations occurred at Group companies in or outside Japan.