News Release

News

FUJI OIL HOLDINGS

Progress report on responsible palm oil sourcing

2020.6.30

1. PURPOSE

Fuji Oil Group (Fuji) formulated and announced its Responsible Palm Oil Sourcing Policy in March 2016. The Responsible Palm Oil Sourcing Policy outlines commitments towards a No Deforestation, No Peatland and No Exploitation (NDPE) policy for all palm oil production within our supply chain – Fuji Oil Responsible Palm Oil Sourcing Policy.

https://www.fujioilholdings.com/pdf/en/csr/sustainable/160310.pdf

The progress on our initiatives to implement the Responsible Sourcing Policy is shared every six months to our stakeholders. This report will provide information on new developments made since June 2019.

2. PROGRESS

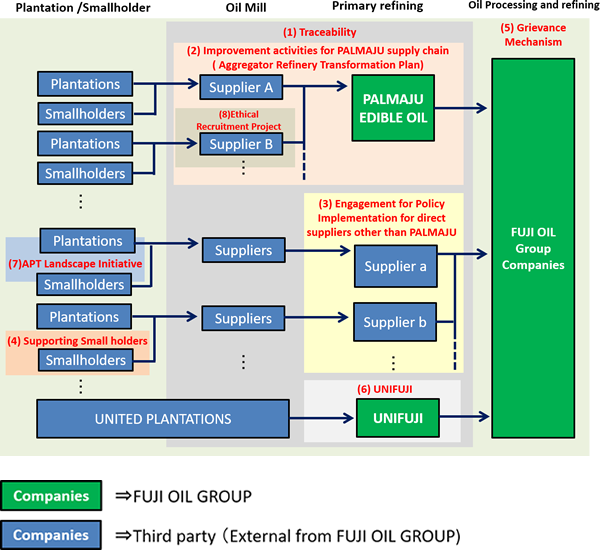

Fuji carries out a number of key activities to promote our Responsible Palm Oil Sourcing Policy as explained in Figure 1. This report focuses on 4 activities which have made progresses since June 2019:

- Traceability

- Grievance Mechanism

- Improvement Activities for Palmaju Supply Chain

- Supply chain improvement with T4T platform (Tools for Transformation)

- Engagements to implement “No Exploitation” commitments [LTP: Labor Transformation Program]

- Engagements to implement “No Deforestation” commitments

- APT (Areal Prioritas Transformasi) Landscape Initiative (Indonesia – Sumatra)

To enable us to meet our Responsible Palm Oil Sourcing Policy goals, we work together with smallholders, millers, refiners and suppliers to identify and address gaps within our supply chain.

<Figure 1: Overview of Main Activities to Improve Fuji’s Responsible Palm Oil Sourcing Policy>

■Traceability

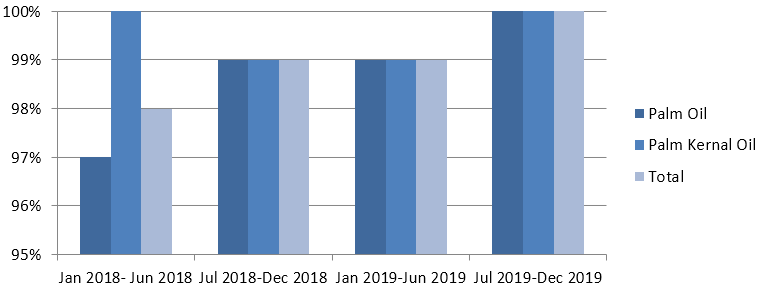

Fuji aims for a transparent NDPE (No Deforestation, No Peatland and No Exploitation) compliant supply chain and plans to achieve full traceability to mills for all palm oil purchased and processed across the Group by 2020.

We are proud to announce that we have achieved a global palm oil traceability to mill score of 100 % for the period from July 2019 to December 2019, which is an improvement from the last reporting period (from January 2019 to June 2019). This means achievement of 100 % for both Palm Oil (PO) and Palm Kernel Oil (PKO) products across all Fuji Business units across the world.

<Figure 2: Transition of Traceability Score to Oil Mills>

The continuous efforts in strengthening communication with suppliers within all Fuji’s sourcing regions and across all Fuji business units have attributed to the increase in the traceability as illustrated in Figure 2.

Fuji is committed to supply chain transparency as stated in our Responsible Palm Oil Sourcing Policy and will continue to strengthen engagement with suppliers to maintain the full traceability scores to mill. Besides on continuous efforts to maintain the full Traceability To Mill, FUJI also announced our new target, 100% Traceability To Plantation by 2030. The Traceability score to plantation is 52% at present. Regarding the new targets, please refer to the URL below.

https://www.fujioilholdings.com/en/news/2020/1198318_2692.html

Note on results

- Traceability levels may vary over time due to data availability, changes in sourcing or other issues.

- All traceability numbers are based on self-disclosed information provided by our suppliers. In some cases, the GPS coordinates of mills were shared with our sustainability partner Earthworm Foundation (EF) and not directly with Fuji.

- Some mill data is bound to NDA’s between EF and our suppliers. Plans for Fuji to hold this data are being developed.

■Grievance Mechanism

We have established and published our grievance mechanism in May 2018 to carry out our NDPE policy. FUJI has revised the grievance procedure in April 2020 to respond to grievances more effectively. The latest Grievance procedure and Grievance list have been published on our Grievance website on the following link:

https://www.fujioilholdings.com/en/csr/grievance_mechanism/

The Grievance List is updated on a quarterly basis and the latest one has been published on June 30th 2020. Fuji continues to monitor, engage and communicate with our suppliers to ensure the grievances raised by various parties are dealt with and managed in accordance to our Commitment.

■Improvement Activities For Palmaju Supply Chain Aggregator Refinery Transformation Plan

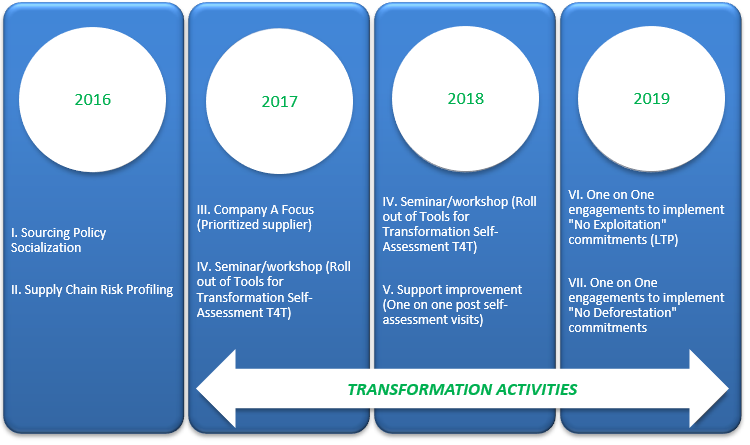

Since July 2016, we have partnered with Earthworm Foundation to implement our Responsible Palm Oil Sourcing Policy. As part of the policy implementation strategy, we have embarked on an Aggregator Refinery Plan (ART)i for the Crude Palm Oil (CPO) and Palm Kernel Oil (PKO) suppliers in the supply chain of Palmaju Edible Oil which is our group’s first refinery in Malaysia.

The ART plan is aimed to provide support to enable changes to take place on the ground through our partners in the supply chain which ranges from refiners, millers to growers. This is implemented through various activities that meets the need of our partners. This ranges from seminars and workshops, one on one engagements and assessments on the ground. The ART plan process can be seen in Figure 3.

<Figure 3:The ART Plan Process>

We have grouped the activities into three categories as below:

① Transformation activities with company A:

② Transformation activities with suppliers other than company A:

③ Other engagement activities:

① Transformation activities with company A (Prioritized Supplier) – [Completed in 2017]

Please refer to the video link below for the achievements we did with company A:

https://www.youtube.com/watch?v=sUWBgu07Tp8

Several milestones were achieved by company A, in which their good practices and progress in their sustainable transformation journey were shared at EF’s Pioneer Forum in 2018.

Pioneer forum is an event for palm oil plantations and oil mills to share good practice.

The following link provides more information on company A and the Pioneer Forum:

https://sway.com/pLEOS156F4OgnrC7

② Transformation activities with suppliers other than company A [On-going]

Of the processes shown in Figure 3, the following two processes apply.

Ⅳ. Seminar/ workshop (Roll out of Tools for Transformation Self-Assessment T4T)

Ⅴ. Support improvement (One on one post self-assessment visits)

Fuji has been using the Tools for Transformation Self-Assessment (T4T)ii scale up our transformation efforts and to help our palm oil suppliers to self-assess their practices while understanding where they stand against Fuji Oil Responsible Palm Oil Sourcing Policy requirements (No Deforestation, No Peat, No Exploitation). The tool is useful to both suppliers and us to understand the supplier’s current status versus Fuji’s Policy.

A total of 48 entities have been engaged and have attended the workshops on T4T in 2019. The uptake in assessments by mills and plantation have also increased since 2018 as shown in Figure 4 and this shows that our suppliers are equally committed to improve their practices.

<Figure 4: Total Number of Completed T4T Assessments for 2018 and 2019>

| Number of completed T4T assessments FY 2018 | Number of completed T4T assessments FY 2019 | ||

|---|---|---|---|

| Palmaju | Mill | 7 | 8 |

| Plantation | 5 | 10 | |

| Indirect suppliers | Mill | - | 14 |

| Plantation | - | 11 | |

For 2019, T4T had included Action Plan module in the system. Suppliers who have responded to the questionnaire will be provided with an action plan to address the gaps found through the answered questionnaire. Guidance on how to deal with these gaps (if any) can be found in the Tools for Transformation Resources website

(https://toolsfortransformation.net).

<Figure 5: T4T: An Integrated Monitoring/ Transformation Platform>

Besides being able to measure the progress of our suppliers against NDPE, this tool provides a good opportunity for Fuji to engage with a wider group in a more efficient manner and develop a better relationship with its suppliers.

③ Other engagement activities [On-going]

Of the processes shown in Figure 3, the following one process applies.

Ⅵ. One on One engagements to implement “No Exploitation” commitments [LTP]

Our work through T4T has also enabled us to have a better visibility on the need to strengthen our transformation work to improve Labor practices and standards in the industry. We recognize the need to eliminate forced and bonded Labor within the palm oil supply chain and it is a priority for key palm oil suppliers and buyers especially due to market demand for NDPE compliant supplies. This support is especially useful for small and medium sized entities to embark on transformative activities especially in alleviating Forced and Bonded Labor.

In that context Fuji Oil decided to initiate One on One engagements to implement “No Exploitation” commitments (The Labor Transformation Program)

In that context, in H2 2019, Fuji Oil has intensified its efforts to engage with its key suppliers through one on one engagements to implement its “No Exploitation” commitments : The Labor Transformation Programiii is direct and focused to help millers improve and close gaps in key Labor practices such as ( but not limited to) :

- ⅰ. Passport Retention

- ⅱ. Ethical Recruitment

- ⅲ. Employment Contract

- ⅳ. Grievance Mechanism

Four visits were carried out with 2 key entities within Palmaju supply chain in 2019. Unlike traditional field assessments, LTP focuses on transformation and allows improvement in key Labor practices to be tracked and measured. Thus, providing qualitative and quantitative incentives for suppliers to adapt to new market (NDPE) requirements and change their practices. Tailored support and assistance was also provided to the engaged entities for them to achieve the standards expected within the time frame set during the visits.

FUJI will continue to promote Labor Transformation Program (LTP). We announced that we aim to 100% appliance of LTP to suppliers with regard to Palmaju by 2025. For more details of the announcement, please refer to the URL below;

https://www.fujioilholdings.com/en/news/2020/1198318_2692.html

③ Other engagement activities:

Of the processes shown in Figure 3, the following one process applies.

Ⅶ. One on One engagements to implement “No Deforestation” commitments

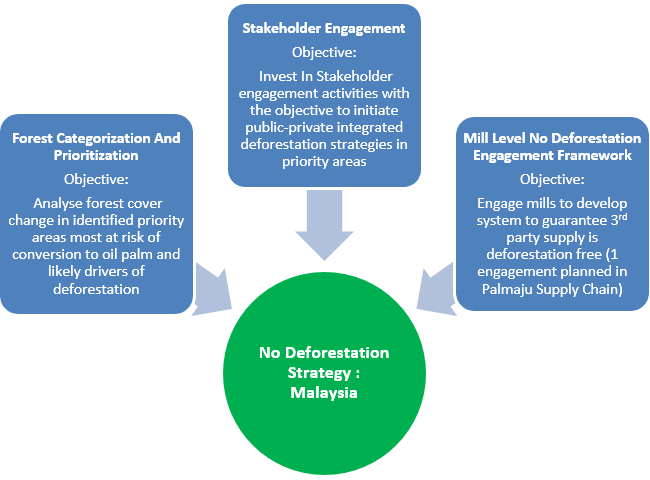

At Fuji we are guided by our Responsible Palm Oil Sourcing Policy and we are committed to ensure that our supply chain is free from deforestation and development on peatlands. In order to achieve this, we are collaborating with our sustainability partner and other industry players to shape a No Deforestation Transformation Strategy in Malaysia.

A series of strategic activities were designed to complement the Theory of Change drawn by our sustainability partner Earthworm Foundation. The activities as shown in Figure 6 intends to maximize our impact on deforestation, drive efficient implementation of No Deforestation commitments and policies based on a two-pronged strategy aimed at both private and public engagement.

<Figure 6: No Deforestation Strategy Activities and Objectives>

All the objectives set out in 2019 were met.

Significant progress was made through this collaboration. Key achievements in 2019 includes:

- A baseline heat map of Malaysia to steer the engagement strategy with suppliers and government agencies to focus on priority areas

- Spatial analysis on 3 study sites in Sabah to understand drivers of deforestation

- Stakeholder meetings with the Ministry and relevant department heads

- Development of guidance documents to Implementation Traceability to Plantation.

We will continue to work together with EF and other parties to build on the foundation laid in 2019 to move towards a more integrated approach to address palm oil driven deforestation in priority landscapes.

■APT Landscapes Initiative – Indonesia

Almost 60% of Fuji’s supply comes from Indonesia and this remains a key sourcing supply for our supply chain.

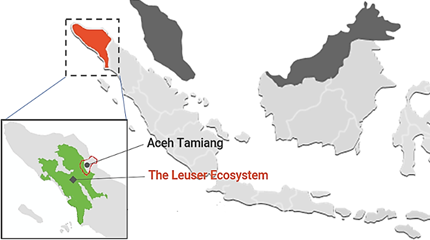

Fuji joined the Areal Prioritas Transformasi (APT)iv or Priority Transformation Areas initiative in Aceh Taming, Indonesia in 2018 to reduce deforestation and demonstrate the feasibility of balancing commodity production, nature conservation and good social and Labor practices at scale.

<Figure 7: Location of Aceh Tamiang Landscape with respect to the Leuser Ecosystem>

Our involvement in the last two years has delivered positive impacts and continues to achieve new milestones. Some notable achievements between June to December 2019 includes:

- Securing the first formal support of government in the Southern Aceh landscape

- Growing enthusiasm from local communities engaged in Livelihoods Program pilots

- Eagerness of government authorities in Aceh Tamiang to urgently translate visionary sustainability commitments into tangible action, as evidenced by the formation of the Task Force for the Acceleration of Green Development by the Bupati

- Decrease in the trend of deforestation in Aceh Tamiang and Southern Aceh

Another notable highlight for the second half of 2019 for this initiative was the trip organized for funders to get their boots on the ground. Fuji was thrilled to be able to see the development of the work done in Aceh Tamiang and issues involved when implementing commitments to protect forests and the livelihoods of people working and living there.

3. NEXT STEPS

In 2020, Fuji will persist with its efforts to uphold its Responsible Sourcing Policy.

FUJI has published our mid-to-long term goals for sustainable sourcing including KPIs of palm oilin June 2020. We consider that switching all raw materials to sustainable ones is an essential strategy to enhance the sustainability of the Group's business. We will make further efforts to achieve the milestone for NDPE. For more detailed information about the mid-to-long term plan, please refer to the URL below;

https://www.fujioilholdings.com/en/news/2020/1198318_2692.html

Fuji will continue implementing its strategy across the supply chain. Traceability efforts will be focused more on developing a governance in managing TTP (Traceability To Plantation). Additional one on one engagements with key suppliers will be performed to implement “No Exploitation” & “No Deforestation” commitments. We will also continue to scale up our efforts by leveraging the Tools for Transformation platform.

We also see the need to strengthen our capacity internally to enable us to engage more regularly with our suppliers and ensure proper follow up activities on all our previous engagements. On top of this, we will continue to review and respond to grievances raised through our Grievance Procedure, in which all grievances will be listed in our Grievance List after verification. Fuji will also continue to update its supply chain data and our traceability score will be released publicly on a half-yearly basis on our dedicated dashboard.

Please stay tuned for further information in our next progress report which will be released in December 2020 along with our activities on palm oil sustainability.

i ART Plan

https://www.earthworm.org/news-stories/art-episode-1-how-tft-works-in-palm-oil-an-introduction-to-the-art-plan

https://www.earthworm.org/news-stories/art-episode-2-traceability-getting-to-the-heart-of-things

https://www.earthworm.org/news-stories/art-episode-3-mpp-plotting-the-road-map

ii Tools for Transformation (T4T)

T4T is an online system created and managed by EF to help palm oil refineries engage their suppliers to improve practices on the ground and report progress. This automated system uses the power of digital technology to transfer and collect huge amounts of sustainability data, generate automated action plans, link businesses with a know-how library and empower step by step transformative change on the ground.

iii Labor Transformation Programme

The LTP is a supplier engagement initiative focused on transformation around key Labor issues developed by EF in 2019.

iv APT Landscape - Indonesia

https://www.earthworm.org/our-work/projects/aceh-tamiang-sumatra-indonesia